Thermoforming

DaVinci Molding offers ISO9001-2015 quality and has ISO Class 8 cleanroom capabilities enabling the production of sterile, barrier packaging systems for pharmaceuticals and medical devices.

We run single sheet forming with plug assist to achieve high quality prototypes, close to production quality. Additionally, we offer small inline pressure forming equipment to provide production quality in pilot run volumes. 100 to 5,000 lots. These parts can be used to validate a package for 510k submission. Lastly, we have high volume electric pressure forming with in-line trim and automated stacking thus maximizing the economics of a thermoform part.

Tooling capabilities run from rapid prototype tools [1 week] to complete CNC machined molds running out from 10 to 12 weeks lead times depending upon complexity. Pilot tools can run in the 4-to-5-week lead times.

Blowmolding

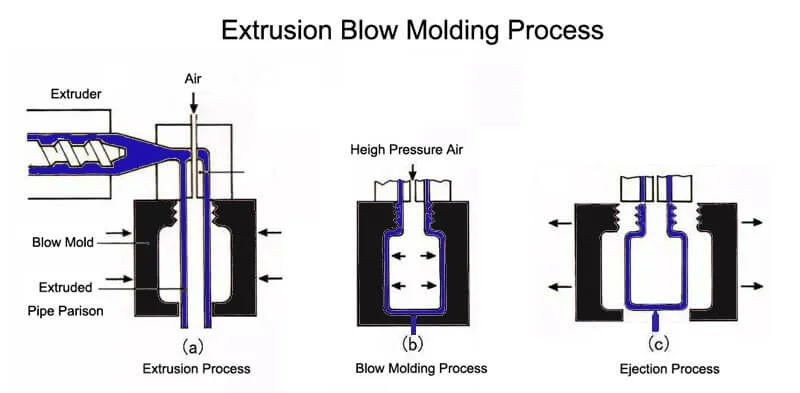

Blow Molding can be thought of as like thermoforming with a parison forced into the cavity design via air. Considerations of material stretch, part geometry all must be considered during the engineering and design phase of a blow molded part. Tooling is more complex than thermoforming with all components of a mold integral to the final mold design.

We run multiple reciprocating screw extrusion blow molding machines in temp controlled environment, and all parts are flame treated around the parting line for smooth finishes. Material options include PE, PP, TPE, SBC, and we color match as needed.

With more than 30 years of experience, we have mastered details – such as selecting head tooling and fully programmable control for consistent parison weight distribution – to give you high-quality blow-molded bottles, custom plastic containers and blow-molded plastic parts.

Production Tooling run from 8 to 12 weeks and engineering samples can be 3d printed for evaluation during part creation.

Secondary Operations include – CNC machining, ultrasonic insertion [screw inserts], heat staking, hot stamping, pad printing riveting, sonic welding, assembly, liquid filling, kitting, labeling and packaging.

Injection molding

Low-volume injection molding is as important to us as our higher volume work. We give every project the same high level of care and attention regardless of quantity.

Our skilled operators use state-of-the-art all electric presses to deliver high-quality engineered plastic parts in any quantity. We are adept at manual inserts and hand loads for low-volume molding. Our robotic systems speed insert loading and finished part extraction when appropriate. We are continuously updating and expanding our injection molding facility

We offer our own range of medical grade polypropylene storage plates and reagent reservoirs consumables which are manufactured in our ISO Class 8 cleanroom. The reservoirs are engineered suitable for use with liquid handling systems. In addition, we specialize in offering custom manufacturing solutions to the life science sector.